-

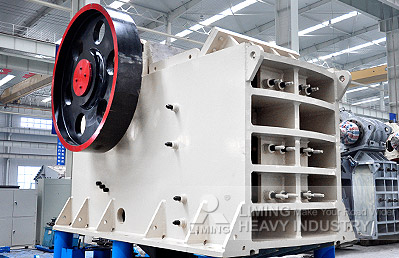

سلسلة CS كسارة مخروطية الزنبركية

سلسلةCSكسارة مخروطية الزنبركية هي التي تتخذ شركتنا بتقنية من الخارج. حسب طلب الزبائن. علي اساس مبدا تصميم التكسير وتكسير اكثرمن ارتداء، جم

-

اسطوانة واحدة كسارة مخروطية هيدروليكية HST

اسطوانة واحدة كسارة مخروطية هيدروليكية لدينا ملخص من عشرين عاما في صناعة تشارك في سحق التصميم والإنتاج والمبيعات والخدمة على أساس من الخب

-

.jpg)

المحطة الكسارة المتنقلة المديل ال

هو بحث نوع الزاحف سحق المحمول ومصنع الفرز ومصممة من قبل المهندسين ذوي الخبرة لدينا.فإنه من أداء مستقر وبنية جميلة.ويستخدم على نطاق وا

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

المحطة الكسارة المخروطية المتنقلة

ونصائح آمنة، وهو مناسب، عالية الكفاءة وآمنة. وناقل حركة أوتوماتيكي المحمولة للعائد مادي جعل تركيب مصنع كامل غاية السهولة. الساقين الهبوط ا

-

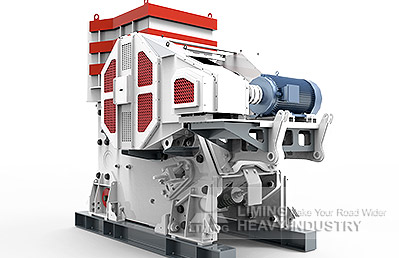

كسارة متنقلة الهيدروليكي بالمجنزر

هو بحث نوع الزاحف سحق المحمول ومصنع الفرز ومصممة من قبل المهندسين ذوي الخبرة لدينا. فإنه من أداء مستقر وبنية جميلة. ويستخدم على نطاق واسع في

-

المحطة الكسارة المخروطية المتنقلة ومغذي الهزاز

بنيت إما كشاشة ضعفين أو ثلاثة أضعاف سطح السفينة مع أو بدون تغذية النطاط، كشاشة الموز، مع سطح فحص الاصبع، مع لوحات مثقبة من المطاط، الخ الشا

-

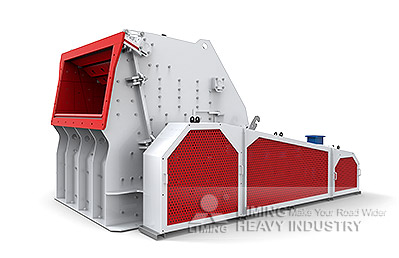

المحطة الكسارة التصادمية العمودية المستقيمة المتنقلة

المحمول VSI كسارات مثالية لسحق العالي والتطبيقات فحص في المحاجر والتعدين، وإعادة تدوير الخرسانة والبنية التحتية والصناعات الإنشائية. ويست

-

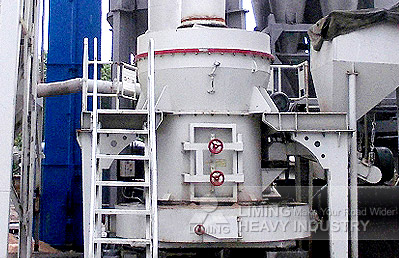

الطاحونه البودرة البندول الرول MB5X

و استنادا الي خبرة الاجيال الاربعة الاولي من طاحونه . و استخدام التكنولوجيا متقدمة و موثوق بها علي براءة اختراع .الطاحونه البودرة بندول الر

-

-

-

TGMطاحونة عالية الضغط شبه المنحرف

ان الطاحونة عالية الضغط TGM تتكون من الكسارة الفكية والدلو المصعد والمخزن والفيدر كهرباء المغناطيس وغرفة التحكم والطاحونة الرئيسية.ان الطا

-

-

Concrete Production an overview | ScienceDirect Topics

103 Biocementation in civil engineering Concrete production is a highly intensive energyconsuming process and presently facing a number of challenges in reducing the carbonConcrete production creates fewer CO 2 emissions than other building materials do Its long lifespan means it doesn’t need to be replaced often, and it can be recycled to create new concrete when it does break down It’s anConcrete Production Process

Concrete Production, Placement, & Curing Process

Concrete Production and Placing Process: 1 Batching of concrete: 2 Mixing of concrete: 3 Transportation of concrete: 4 Placing of concrete: 5 Compaction of concrete: 6A connecting theme throughout each presentation is how concrete is manufactured with quality as the utmost importance The event will offer an indepth insight for Engineers,The Production of Concrete

Concrete Design & Production Cement

Concrete Design & Production Concrete is a mixture of two components: aggregates and paste The paste, comprised of cement and water, binds the aggregates (usually sand and gravel orProduction of Concrete These steps (given below) are involved in the production of concrete Batching of ingredients; Mixing of ingredients; Placing; Curing; Batching of Ingredients ThereConcrete! Components and Production of Concrete Civil

Cement Production an overview | ScienceDirect Topics

The production of cement is either through the wet or dry process with the dry process as the preferred option because of the lower energy intensity Cement production accounts for aboutCement is one of the four raw materials that are used in the production of concrete, along with gravel, sand and water To be exact, concrete consists of 50% gravel, 25% sand, 15% cement and 10% water All four雅思写作小作文范文 雅思写作流程图flow chart 水

Concrete: Manufacturing Process BrainKart

This requires some rules to be followed in the various stages of concrete production and are discussed as follows The stages of concrete production are: 1 Batching or measureme nt of materials 2 Mixing 3 Transporting 4 PlacingWhile the process of making cement uses a number of tools, the production of concrete requires only a concrete mixer In the first stage of making cement, limestone and雅思写作小作文流程图考官范文:水泥制作与生产雅思

Concrete! Components and Production of Concrete Civil

The basis for mixing by volume is usually one part of concrete in n parts of sand and 2 parts of ballast Ballast is usually double compared to sand The cement/sand ratio depends on the desired strength of the concrete The ratio is lower when high strength is required The volume of a 50 kg bag of cement is 345 litresThis one day Technical Seminar aims to provide an overview of the methods of producing concrete A connecting theme throughout each presentation is how concrete is manufactured with quality as the utmost importance The event will offer an indepth insight for Engineers, Graduates, Producers, Constituent Suppliers and Apprentices with a focusThe Production of Concrete

Concrete Design & Production Cement

Concrete Design & Production Concrete is a mixture of two components: aggregates and paste The paste, comprised of cement and water, binds the aggregates (usually sand and gravel or crushed stone) into a rocklike mass as the paste hardens A properly proportioned concrete mix possesses acceptable workability of the freshly mixed concrete andAt the cement production factory, the proportions of the various raw materials that go into cement must be checked to achieve a consistent kiln feed, and samples of the mix are frequently examined using Xray fluorescence analysis The strength of concrete is probably the most important property that must be tested to comply with specificationsHow concrete is made material, manufacture, making,

What Equipment is needed for the production of concrete

For the production of concrete blocks, cement, sand, stone dust, and crumb are used, with a diameter of 3 to 5 mm These are the most common materials for the production of all types of concrete blocks and bricks By mixing individual ingredients in different proportions, we can obtain different types of blocks and bricks, including hollowThe high alkalinity and LOI values of bioashes can negatively affect freezethaw resistance of concrete, but this was not observed in the research by Ref [221]; other studies [252] showed that(PDF) APPLICATION OF WOOD ASH IN THE PRODUCTION

Concrete Definition, Components, Grades, Manufacture,

Concrete is a construction material composed of cement, fine aggregates (sand) and coarse aggregates mixed with water which hardens with time Portland cement is the commonly used type of cement for production of concrete Concrete technology deals with study of properties of concrete and its practical applicationsFor every ton of cement produced, approximately 2,400 pounds of carbon dioxide are released Carbon dioxide emissions from the production of concrete stem from two primary sources: the energy used in the production of cement and the chemical process of calcining limestone into cement (CaCO3 > CaO + CO2) Each is a major contributor (Table 2)Concrete Energy Consumption Green Building

The Environmental Impacts of Concrete MEKA

Significance of concrete production in terms of carbondioxide emissions: social and environmental impacts”, Politeknik Dergisi, 21(2): 369378, (2018) 2 Betonarme yapım sistemlerinin ekolojik açıdan değerlendirilmesi Doç DrPDF | On Sep 1, 2014, Yahya Jani and others published Waste glass in the production of cement and concrete – A review | Find, read and cite all the research you need on ResearchGateWaste glass in the production of cement and

Production of cement and concrete | KRÜSS Scientific

Production of cement and concrete Interfacial chemistry measuring methods for the material behavior before and after setting Hardness and longevity make concrete the Number One industrial building material As well as the main constituents of cement, gravel, sand and water, a whole range of interface active additives are availableThe production of concrete is continuous precision work A successful precast operation demands a proper understanding and management of concrete technology Since concrete is the primary raw material for precast products and structures, it has an important influence on quality, production effectiveness and costsThe ABCs of concrete production Elematic precast

characterization of raw materials for the

The 24hour concrete compressive strength for the ligno sample characterized by 138 mm was 3 MPa while the concrete produced with the 165 mm batch showed no strength after 24 hours The concrete was still soft after 24 hours and builtProduction of Cement Engr Sajid Chaudhary Cement is a powdery substance made by calcining lime and clay, mixed with water to form mortar or mixed with sand, gravel, and water to make concrete Cement is made by grinding together a mixture of limestone and clay, which is then heated at a temperature of 1,450°C(PDF) Production of Cement | Engr Sajid Chaudhary

IELTS Task 1 Process Cement and Concrete

Making concrete is a simpler process that involves mixing four ingredients in a concrete mixer Limestone and clay are crushed and the resulting powder is then mixed before being passed through a rotating heater OnceAdequate water cement ratio is required for production of workable concrete When water is mixed with materials, cement reacts with water and hydration reaction starts This reaction helps ingredients to form a hard matrix that binds the materials together into a durable stonelike material Concrete can be casted in any shapeConcrete Definition, Components, Grades, Manufacture,

Concrete Energy Consumption Green Building

Approximately 90 percent of the energy required to produce a viable concrete is consumed during the process of producing cement in the kiln As a result of the very high temperatures used in cement kilns (1480°C, or 2700°F), hazardous materials may be burned relatively safely because the high temperatures result in very nearly complete combustionOn average approximately 1 ton of concrete is produced each year for every human being in the world Therefore concrete is one of the World’s most significant manufactured materials Because of its abundance in the worldThe Environmental Impacts of Concrete MEKA

Visualizing the Annual Production of Sand,

The Concrete Facts of Cement Cement is the indispensable glue that binds together the materials that make up concrete highways, sidewalks, and buildings With concrete being the world’s most consumed material (beatenThus, concrete is known by its compressive strength M20 and M25 are the most common grades of concrete, and higher grades of concrete should be used for severe, very severe and extreme environments 2 Compressive strength of10 Properties of Concrete and their Uses The

[fxp:title]

the production of concrete